Information Possibly Outdated

The information presented on this page was originally released on June 16, 2015. It may not be outdated, but please search our site for more current information. If you plan to quote or reference this information in a publication, please check with the Extension specialist or author before proceeding.

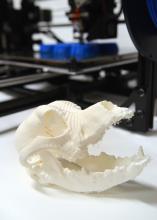

3D printer enhances VSC technology, abilities

Veterinarians at the Mississippi State University Veterinary Specialty Center (VSC) are using 3-D printer technology to make models of spinal and skull injuries that help them develop better treatments for their animal patients.

The VSC purchased a Lutzbot Taz 4 3-D printer last year, and it is now one of the center’s most valuable pieces of equipment. Three-dimensional models from the printer allow specialists and practicing veterinarians to view internal trauma without the use of invasive procedures.

“Overall, we have used it to look at spinal and skull injuries in the animals referred to us and to find new ways to correct them,” said Dr. Andy Shores, chief neurosurgeon and neurologist with the MSU College of Veterinary Medicine. “We take CT scans of spinal injuries, convert them into three-dimensional images on a screen, and convert those to files that can transmit that information to the printer. The result is a plastic model identical to what was on the screen.”

The VSC, a CVM satellite facility located off campus in Starkville, specializes in neurologic, neurosurgical and ophthalmologic care. Veterinarians in the center perform radiation therapy and advanced imaging for pets suffering from brain tumors, spinal injuries or other trauma.

The three-dimensional printer at VSC produces models by shaping molten plastic. The printed designs are rendered using a computer-aided design program.

Shores said the new device is proving especially useful for MSU veterinary students and neurosurgery residents because it allows the center to produce and preserve models of different types of spinal and skull injuries for future observation and inspection.

“The equipment prints out bony structures, so future students can see exactly how a particular injury looks and get a better appreciation for the condition we’re talking about while on rounds,” he said. “If you have a patient with a broken bone or vertebrae, to be able to put that structure in your hand goes a long way toward the students’ understanding what it is and how to repair it.”

The 3-D printer is also being used in research projects to improve veterinary care, including the development of new technology that would allow pet owners to treat some animal ailments themselves.

“One of our projects has to do with designing a plate that would be put at the bottom of vertebrae for a spinal injury,” Shores said. “We’re also looking at designing an atomizer that is connected to a nasal catheter to be used for home emergencies such as seizures. We have a design that will be part of a physical therapy device to help dogs with mobility issues move their back legs.”

Shores said he is hopeful that the VSC will soon purchase a 3-D printer capable of producing structures made of biocompatible materials that can be implanted into an animal’s body.

“If we have a dog that has a badly fractured vertebrae that can’t be repaired and will continue to deteriorate, a biocompatible device allows you to take dimensions of the vertebrae, reconstruct them on a screen, print it out, and replace the body part,” Shores said. “The limitations of a three-dimensional printer in medicine and surgery have to do with your imagination. The technology is a crucial component in the future of surgery and medicine. We don’t want to be reading about it. We want to be a part of it and be at the forefront.”

Dr. Andrew Mackin, professor and interim head of the CVM Department of Clinical Sciences, said having the new equipment in the VSC arsenal keeps the college in step with the top veterinary programs in the country.

“Our neurology team is working at the scientific cutting edge with their creative use of this new technology,” Mackin said. “The direction that Dr. Shores and his group are taking is exciting. What seems almost like it is lifted straight from the pages of science fiction today will become the standard of care for our veterinary patients in the near future."

Contact: Dr. Andrew Mackin, 662-325-6631