Artificial Regeneration of Bottomland Hardwoods

Artificial regeneration in hardwoods involves planting acorns or seedlings, compared with using existing trees as a seed or sprout source in natural regeneration. While natural regeneration is typically considered the best option for regeneration for economic and efficiency reasons, it is not always feasible—usually because there isn’t an existing source of seeds or sprouts.

Some hardwood stands can produce only small amounts of seedlings or saplings in the understory due to a limited source of regeneration. In this situation, artificial regeneration may be needed only to supplement advanced regeneration numbers. However, in many instances, no provision is made for ensuring establishment of advanced regeneration before harvesting, the desired species being regenerated was not present in the previous stand, or no trees existed at all (such as in retired agricultural areas). Artificial regeneration is the only recourse for managers establishing desirable species in postharvest stands in these cases.

While many nonoak species (ashes, maples, elms, etc.) have values associated with various management strategies, they often have serious negative competitive effects on developing oak seedlings. Oaks are important commercially for production of wood products. They also provide shelter and food for many species of wildlife, as well as aesthetic and environmental benefits. When these factors are combined, oak species are often viewed as the most valuable species group for many management objectives. Consequently, this publication will focus on information related to the artificial regeneration of oak species.

Species-Site Relationships

Several factors, including seedling quality, handling during lifting/storage/transport/planting, vegetative competition, environmental variables, and species-site relationships, can influence survival of oak regeneration in artificial regeneration attempts. Of these, mismatching species to a site is one of the more common mistakes made by managers practicing artificial regeneration. Unlike pine silviculture, different hardwood species often do not have a wide range of site suitability. Even within the same species group, different species may have vastly different soil, moisture, and nutritional tolerances. For example, cherrybark oak is unsuitable for growing on wet, clay soils of higher pH. Managers who ignore these basic traits have met with regeneration failures in past attempts. Without acknowledgement of species-site relationships, artificial regeneration efforts in bottomland hardwood stands often fail.

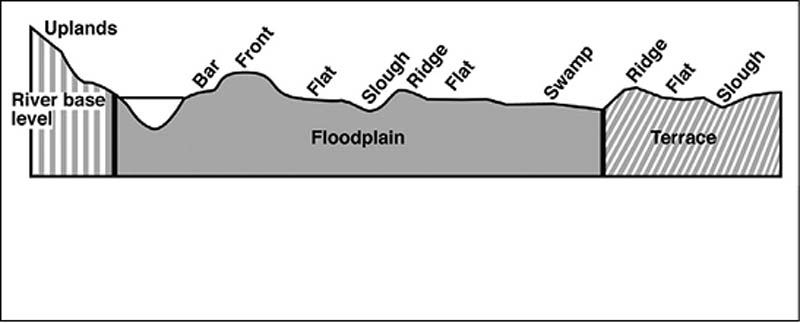

A bottomland hardwood stand refers to hardwoods growing on floodplain sites. These sites have highly variable soils with a wide range of productivity, species suitability, and species that inhabit the stands. Site changes are driven by elevational changes due to variable soil deposition during flooding events. Elevational changes of as little as 6 inches may completely change site suitability for a given species due to variations in drainage class, onsite vegetation, and soil texture, structure, or pH, among other factors. All should be considered in the context of species/site assessment before deciding which species to regenerate on a given site. For a more thorough explanation of bottomland hardwood species/site relationships, please read MSU Extension Publication 2004 Bottomland Hardwood Management: Species/Site Relationships.

Planting Quality

During the first growing season after planting, an oak seedling usually does not produce much above-ground growth, which leaves survival—not growth—as the primary concern. If planting quality is poor, nutrient uptake and water uptake suffer. In addition, root systems will dry out if not properly covered and packed. These factors lead to seedling mortality and planting failure. Poor planting quality is very influential in oak planting failures commonly found across the South. Proper planting is a process that includes the actual planting of seedlings and all handling during shipping, storage, and on-site work. Seedlings should be kept cool and moist during shipping and storage. Once on-site, they should be placed in a portable cooler. If placement in a cooler is not possible, put them in a shaded area. Seedlings removed from shipping packaging should be placed in planting bags immediately and handled singly during planting. Seedling root systems should not be twisted, balled, or bent when planted, and the soil should be packed tightly around roots with root collars just below ground level.

The practice of root pruning is generally not a concern when planting pines due to their inherently compact and less fibrous root system compared with that of oak seedlings. Currently, many nurseries grow oak seedlings with large, fibrous root systems. Use of these seedlings may dictate that the planting method must be modified; otherwise, the root systems must be pruned. Pruning a seedling’s roots makes it easier to plant and less likely to have twisted or constrained roots in the planting hole. Also, the planting hole is easier to close properly; however, proper root trimming of hardwood seedlings should involve removing only enough of the root system to enable correct root orientation in the planting slit. Excessive root pruning can reduce carbohydrate reserves needed by the seedling for survival post-lifting at the nursery and subsequent transplant shock when planted in the field. For a more detailed discussion of seedling handling and planting technique, please read MSU Extension Publication 1776 Planting Southern Pines: A Guide to Species Selection and Planting Techniques.

Planting Method

Oak plantings are established either through hand planting or machine planting. Hand-planting contractors use a variety of planting tools. Planting tools may vary among contractors, and the proper tool might change across any given site due to variation in site conditions. Hardwood seedlings have larger root systems than pine seedlings and require a larger planting slit. Consequently, the planting tool should have a blade of at least 10 inches long by 6 inches wide. The large fibrous root systems of some seedlings may dictate considerably larger planting holes. A practiced hand-planting crew can plant between 600 and 1,000 seedlings per planter per day. When employing larger planting crews, hand planting is faster than a one-tractor, machine-planting crew. On the other hand, due to hand-planting labor requirements, machine planting may be less expensive. Discrepancies arise regarding which technique results in better stand establishment. Some of this inconsistency probably results from the poor hand-planting quality encountered in many operational settings.

Generally, machine planting is more efficient than hand planting. It is typically accomplished with agricultural tractors of varying sizes. A planter specifically designed for planting trees is used. These planters open a planting slit in which seedlings are placed. Heavy packing wheels pack soil around seedling root systems. A one-tractor, machine-planting crew can typically plant between 15 and 25 acres per day in good soil conditions. One concern warranting attention is that of heavy clay soils. If a site has these heavier soils, a machine planter may not close the planting slit properly, leading to cracking and root desiccation. Typically, when implemented correctly, there is little difference in growth or survival of seedlings planted using either method. However, some studies have shown machine planting to be superior.

Herbaceous Weed Control (HWC)

Competing vegetation is often the most influential factor in artificial regeneration failures. While chemical site preparation is considered necessary in pine establishment, it does not provide growing season control of herbaceous competition that typically affects oak seedling survival in plantings. Chemical site preparation should be used only to control species that cannot be eliminated by growing season HWC efforts. It is these herbaceous release applications that typically provide longer term control of competition if the proper herbicide is used. Chemical site preparation is of limited value if it does not control vegetation throughout the first growing season. Therefore, when chemical control is deemed necessary to control existing onsite vegetation, it should only be part of a herbicide regime that includes first growing season HWC.

With oaks, it is very likely that an application of a growing season herbicide for HWC is needed to obtain adequate levels of seedling survival during the first growing season. Root systems of freshly germinated and planted seedlings encounter severe underground moisture competition from herbaceous vegetation. In addition, aboveground competition occurs in the form of shading from faster growing herbaceous weeds. Both forms of competition impede establishment of oak seedlings in regeneration attempts where vegetation control is not used. The standard HWC treatment used in oak regeneration efforts involves a preemergent application of Oust XP at a rate of 2 ounces per acre. For more information on HWC and other herbicide uses in hardwoods, please read MSU Extension Publication 2873 Herbicide Options for Hardwood Management.

Mechanical Site Preparation

Mechanical site preparation may be needed on some planting sites, especially those formerly in agricultural production. Mechanical treatment of the soil may be needed to correct compaction problems. While several treatment types exist, disking, subsoiling, and bedding are commonly encountered in bottomland hardwood planting efforts. While information is presented for these three mechanical site preparation treatments, more thorough and detailed information can be found in MSU Extension Publication 3006 Mechanical Site Preparation for Forestry in Mississippi.

Disking

Disking involves pulling a disk across the site to be regenerated. Soils are mixed and loosened, competing plant roots are severed, and a mineral surface is created. The goal is to create a flat mineral surface; however, depending on the disk, ridges and large soil peds may form and impede planting. While the practice has been recommended for site preparation to improve growth and survival of planted oak seedlings, research observations have been somewhat contradictory regarding its effects. Herbaceous control is short term only, and compaction layers are not corrected. When the cost of the operation is considered in conjunction with the overall lack of benefit, disking is not recommended in most artificial regeneration efforts.

Subsoiling

Also known as ripping, subsoiling is performed by pulling a shank through the soil to fracture restrictive layers. The practice can be a valuable tool in regenerating compacted areas—such as retired agricultural fields and retired pastures—as it may increase seedling survival and potentially enhance root and stem growth. It can improve seedling survival and growth as a result of increased moisture availability, more uniform planting depths, better deep root development, and soil exploitation by roots.

If winged tips are used in traditional parabolic-shank subsoiling, planting should not occur for up to 1 year due the size of the slit created. However, areas treated using a no-till subsoiling system may be planted as soon as a month after treatment, assuming the planting slit has closed appropriately. Be careful when subsoiling in high shrink-swell clays, as cracking along the slit can occur. This problem can cause soil drying during the growing season, resulting in seedling mortality from root desiccation. Subsoiling exposes less mineral soil than other forms of mechanical site preparation, and it typically results in lower numbers of undesirable germinated weeds. It is the least expensive and most easily performed of all mechanical treatments due to widespread availability of contractors and the overall simplicity of the treatment. In addition, subsoiling aids in achieving accurate seedling densities. Once it is performed, planting crews can plant along the subsoil slit without concern for row spacing.

Bedding

Also known as hipping or mounding, bedding is typically performed with a moldboard plow, offset disk, levee plow, or furrow plow. Soil is turned inward, creating a planting site 3 to 6 feet wide and between 6 inches and 2 feet high above the soil surface. Bedding is sometimes used in establishment of seedlings on poorly drained soils. Seedling survival in inundated and/or saturated areas is increased by bedding due to raising seedling root systems above the zone of saturation. Many oak species are not tolerant of poorly drained soils and benefit from even slightly higher elevations. In addition, early growth of hardwood seedlings can be increased through improved soil aeration and drainage, concentrated organic matter and nutrients, and short-term competition control.

Planting Stock Considerations

There are three planting stock types that may be used when artificially regenerating oaks: direct seeding of acorns, bare-root seedlings, and containerized seedlings.

Direct Seeding

Direct seeding is the sowing of seed on the soil surface, or shallow planting in the soil. This practice was common in the South before the 1990s but became less widespread as planting bare-root seedlings gained popularity. Direct seeding of acorns has definite benefits. It is less expensive than planting seedlings. Production, transport, and planting costs are lower compared with planting seedlings, and germinated acorns will undergo natural root development without lifting damage and transplanting shock. Germinated oak seedlings exhibit less initial growth than that of planted seedlings because acorns have fewer stored nutrients available for root development and height growth. Properly tested, cold-stratified (period of cold treatment that stimulates germination), and planted acorns have average germination rates of around 35 to 40 percent, but operational success has been limited.

Direct seeding research in Wetlands Reserve Program lands in the early 1990s found it was successful on only 8.4 percent of land being converted to forest (Schweitzer 2004). There are several reasons that germinant survival and direct seeding failure is prevalent in many attempts of the method. Seed predation, germination failure due to drought or extreme temperatures, problems with saturated or flooded soils, poor-quality seed, improper planting technique, and competition with herbaceous vegetation can all lead to direct seeding failures.

When direct seeding is attempted, planting should occur late fall through early summer. Plant acorns between 2 and 4 inches deep using a trowel, sharpened stick, hoe, or mechanized planter and pack soil over them after placement. Due to problems detailed above, acorns are planted at much higher densities than seedlings. Rates of 1,000 to 2,500 acorns per acre can be used, depending on severity of mortality factors. Acorn prices vary depending on species variety and availability, as well as the quantity needed.

Bare-Root Seedlings

Currently, the vast majority of hardwood plantings use bare-root seedlings in artificial regeneration. These seedlings are termed “bare-root” due to a lack of soil surrounding root systems after lifting at the nursery. Of the seedling planting stock types, bare-root seedlings are the least expensive to purchase, transport, and plant. They also have the greatest availability, offer much better performance than direct seeding, and offer comparable performance to larger containerized stock if transported and planted correctly.

These seedlings range in size from a few inches to a few feet in height and between a 10th to nearly an inch at the root collar. If all planting variables and site conditions are ideal, larger seedlings with well-developed tops and root systems are more capable of competing with onsite vegetation, resisting browsing and defoliation pressure, and increased growth and survival compared to smaller seedlings. Some nurseries produce extremely large seedlings grown to capitalize on this principle. These larger seedlings undergo special nursery protocols to “enhance” seedling size, vigor, and numbers of first-order lateral roots (coarser roots as thick as or thicker than a pencil lead). However, it is important to remember that larger seedlings can pose significant planting problems if they are too large for the available planting equipment to plant efficiently. In addition, planting and environmental factors are rarely ideal, and smaller “standard nursery-run” seedlings often catch and sometimes surpass these seedlings within a few years of planting. Mississippi State University studies performed over the last two decades have shown this catchup typically occurs within 5 years of planting for both white and red oak species. These studies indicate that standard 1-0 (1 year in nursery bed and was not transplanted in the nursery) bare-root nursery stock seedlings are sufficient to provide excellent survival and growth.

Quality is the most important factor when purchasing seedlings. Proper bare-root seedlings should have 18- to 24-inch tops and 8- to 10-inch root systems. Root systems should have root collar diameters between ¼ and ½ inch with eight or more first-order lateral roots present to provide the best combination of seedling parameters for competitive ability and planting ease. Larger seedlings are more difficult to plant and often result in unacceptable planting quality and/or dieback from transplant shock. In addition, seedlings should be planted at or slightly above the root collar to ensure proper soil tightness around roots. Bare-root seedlings are the least expensive of the seedling planting stocks and range in price from $0.35 for standard 1-0 seedlings to $2.75 or more per seedling for larger stock.

For plantings that use quality seedlings matched to the site and the seedlings receive proper handling from lifting through planting, are afforded proper HWC, and do not encounter limiting environmental variables, 90 percent or greater survival is achievable at the end of the first growing season. While this level of survival is not always observed in operational efforts, it has been achieved in multiple Mississippi State studies when planting under operational limitations. Failure to satisfy any of the limiting variables detailed above can result in decreased seedling mortality or even planting failure.

Containerized Seedlings

Containerized seedlings are grown in tubes or small to large containers for the purpose of encouraging well-developed, undisturbed root systems that are not separated from the soil in which they grow. These seedlings are more limited in availability and are more expensive than bare-root seedlings. Typical cost ranges from $1.50 to $3.50 or more per seedling; however, there are several benefits associated with planting containerized seedlings. Containerized seedlings may be successfully planted over a longer time span than bare-root seedlings, and some research has shown that they can exhibit greater survival than bare-root seedlings. These factors may warrant the use of containerized seedlings where flooding prevents dormant season planting. While survival is not typically problematic with containerized seedlings, one potential problem area is frost heaving in high shrink-swell clays. During extended periods of subfreezing temperatures, containerized seedlings may be heaved from the ground. In areas where this may occur, planting containerized seedlings may be questionable until the possibility of threatening temperatures has passed.

Most containerized seedlings are grown in small tubes or containers, but some are grown in much larger pots and sold as a means of extremely rapid establishment without some of the normally expected cultural and herbicide requirements needed by smaller seedlings. While potted seedlings may offer some survival and growth benefits, they are much harder to plant (by auger or dug hole with shovel) and have several associated problems that can affect survival (exposed root system tops, seedlings washing out of potting medium, dieback, etc.). Potted seedlings are much more expensive than bare-root seedlings, with typical cost starting around $8 and ranging to more than $30 per seedling. Multiple studies performed at Mississippi State University over the past decade indicate that the use of containerized stock is not warranted. Given proper handling and planting, quality bare-root seedlings often surpass containerized seedlings in growth relatively quickly, thus minimizing benefits of larger planting stocks.

While natural regeneration of bottomland oaks is preferable due to the expense associated with artificial regeneration, planting seedlings can be successful. If species are matched to site, proper preplanting and postplanting care is shown, and nature cooperates, planting bare-root seedlings is often the best option for landowners who want to establish oak plantings efficiently with minimum establishment costs.

Additional Reading

Allen, J. A., B. D. Keeland, J. A. Stanturf, A. F. Clewell, and H. E. Kennedy Jr. 2001. A Guide to Bottomland Hardwood Restoration: U.S. Department of Agriculture, Forest Service Southern Research Station, General Technical Report SRS-40, 132 p.

Gardiner, E. S., D. R. Russell, M. Oliver, and L.C. Dorris Jr. 2002. Bottomland Hardwood Afforestation: State of the Art. Proceedings of a conference on sustainability of wetlands and water resources: how well can riverine wetlands continue to support society into the 21st century? U.S. Department of Agriculture, Forest Service: Gen. Tech. Rep. SRS-50. p. 75-86.

Schweitzer, C. J. 2004. Monitoring and Assessment of Tree Establishment in the Wetland Reserve Program in the Lower Mississippi Alluvial Plain. Proceedings 12th Biennial Southern Silvicultural Research Conference; U.S. Department of Agriculture, Forest Service: Gen. Tech. Rep. SRS-71. p. 586.

Self, A. B. 2020. Bottomland Hardwood Management Species/Site Relationships. Mississippi State University Extension Service Publication 2004. 7p.

Self, A. B. 2022. Planting Southern Pines: A Guide to Species Selection and Planting Techniques. Mississippi State University Extension Service Publication 1776. 16p.

Self, A. B., and A. W. Ezell. 2020. Herbicide Options for Hardwood Management. Mississippi State University Extension Service Publication 2873. 8p.

Self, A. B., and J. Kushla. 2022. Mechanical Site Preparation for Forestry in Mississippi. Mississippi State University Extension Service Publication 3006. 8p.

The information given here is for educational purposes only. References to commercial products, trade names, or suppliers are made with the understanding that no endorsement is implied and that no discrimination against other products or suppliers is intended.

Publication 3486 (POD-09-23)

By A. Brady Self, PhD, Associate Extension Professor, Forestry.

The Mississippi State University Extension Service is working to ensure all web content is accessible to all users. If you need assistance accessing any of our content, please email the webteam or call 662-325-2262.